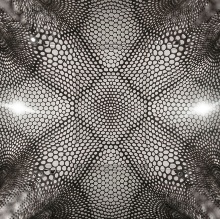

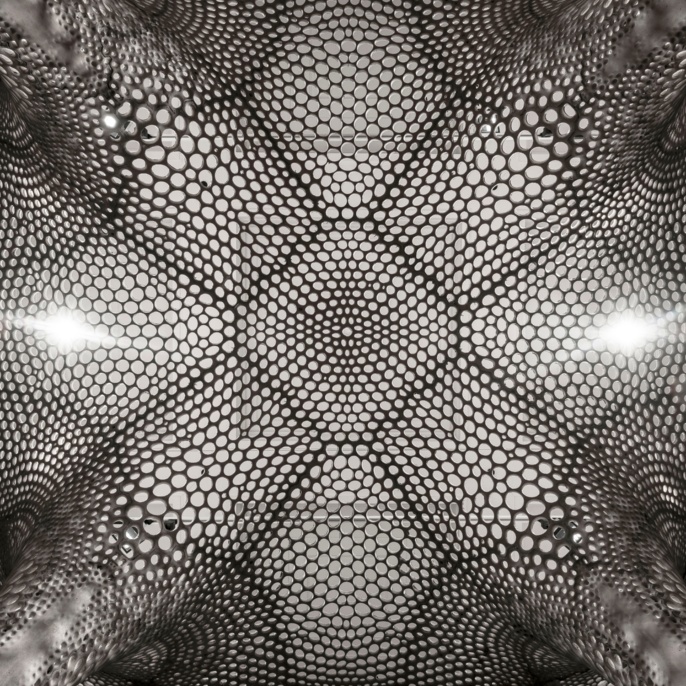

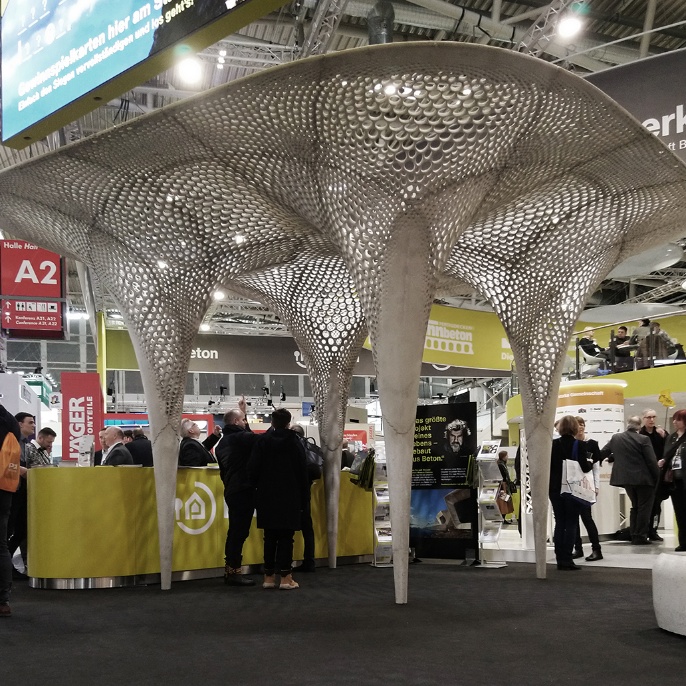

The Rosenstein Pavilion is a contribution to material savings in construction: the porous shell structure is 40% lighter than a solid shell of the same load-bearing capacity. It was developed using optimization methods that place material only where it is statically necessary. This forms the graded porosity that gives it its filigree appearance. It demonstrates that structural optimization unleashes new design potential in architecture.

The Rosenstein Pavilion was designed and built for the special exhibition "Baubionik - Biologie beflügelt Architektur" at Rosenstein Castle in Stuttgart. The exhibition formed the final presentation of all results of the first funding phase of the Collaborative Research Center TRR-141 “Biological Design and Integrative Structures”.

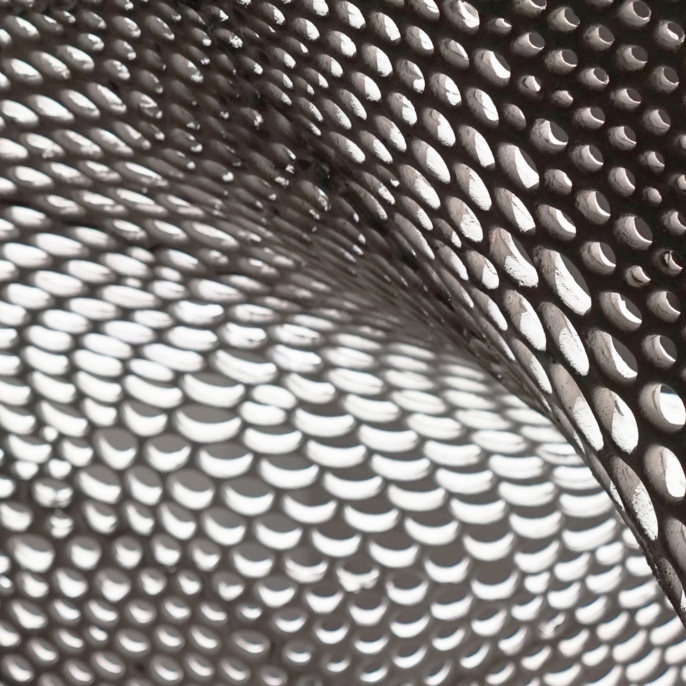

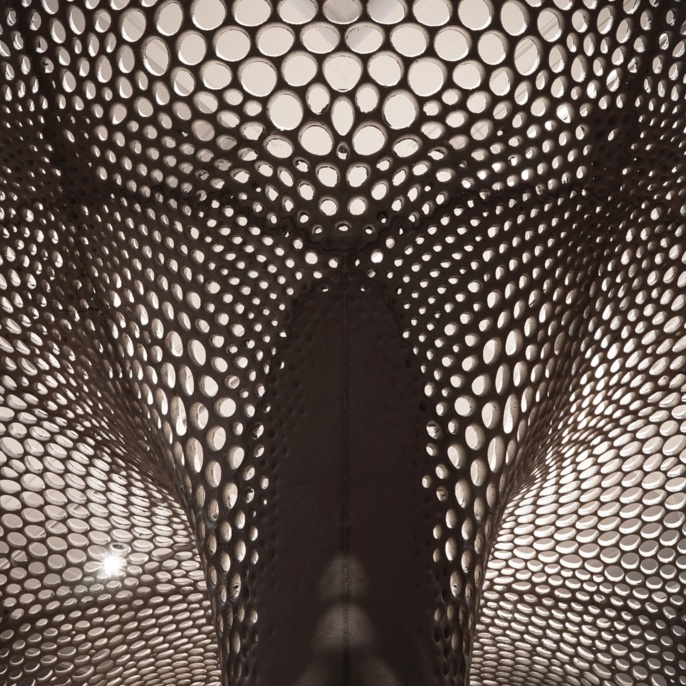

The concept of the pavilion is based on a research project that explores the limits of material savings in building construction by implementing natural optimization strategies. Material conservation is not an end in itself but is intended to contribute to the conservation of finite resources in the building industry. Inspired by high-performance biological tissues, such as bones and exoskeletons, the weight of the structure was therefore reduced by distributing the material according to the state of stress in the structure, also known as functional gradation. To make this principle visible to the visitors of the exhibition, the stress state in the structure was visualized by a functionally graded porosity.

The Rosenstein Pavilion was designed as a porous shell, which, standing on four supports, covers an area of 36 m² and weighs only 1.7 tons due to its optimized internal structure. Thus, the Rosenstein Pavilion is 40% lighter than a shell with a continuously closed surface, while having the same load-bearing capacity. The shape as well as the distribution of the porosity of the shell were developed in an iterative calculation and analysis process until the desired architectural expression was found. The shape of the pavilion is thus a direct expression of the intrinsic combination of form, structure and material. The dimensions of the shell, such as the span between the columns (2.58 m) and the height (3.5 m) were matched to the column grid of the exhibition space. Due to fabrication and transport conditions, the shell was prefabricated in individual segments and assembled on-site.

The Rosenstein Pavilion sees itself as a contribution to a new type of design process in which the goal of conserving resources is actively worked out jointly by architects, civil and mechanical engineers from the very beginning of the project. In this context, structural optimization for the purpose of saving building materials is understood as a design tool for the architecture to come.

After the exhibition at the Natural History Museum in Stuttgart, the pavilion was also exhibited at Stallwächterparty 2018 of the Baden-Württemberg State Representation in Berlin and at BAU 2019 in Munich as part of the stand of the Informationszentrum Beton.

PUBLICATIONS:

Kovaleva, D.; Gericke, O.; Kappes, J.; Haase, W.:

Rosenstein-Pavillon - Auf dem Weg zur Ressourceneffizienz durch Design

Beton- und Stahlbetonbau (6), 2018, https://doi.org/10.1002/best.201800012

Kovaleva, D.; Gericke, O.; Kappes, J.; Tomovic, I.; Sobek, W.:

Rosenstein Pavilion: Design and structural analysis of a functionally graded concrete shell

Structures (18), 2019, https://doi.org/10.1016/j.istruc.2018.11.007

Sobek, W.; Kovaleva, D.; Gericke, O.;

Perforierte Betonschalen

ce/papers, 2019, https://doi.org/10.1002/cepa.993

Kovaleva, D.; Gericke, O.; Wulle, F.; Mindermann, P.; Sobek, W.; Verl, A.; Gresser, G. T.:

Rosenstein-Pavillon: eine leichte Betonschale nach dem Vorbild biologischer Strukturen

Bionisch bauen, 2019, https://doi.org/10.1515/9783035617870-012

PROJECT PARTNERS

Institute for Lightweight Structures and Conceptual Design (ILEK), University of Stuttgart, Prof. Dr. Dr. E.h. Dr. h.c. Werner Sobek

Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW), University of Stuttgart, Prof. Dr.-Ing. Alexander Verl

Institute for Textile and Fiber Technologies (ITFT), University of Stuttgart, Prof. Dr.-Ing. Götz T. Gresser

SCIENTIFIC DEVELOPMENT

Daria Kovaleva, Frederik Wulle, Oliver Gericke, Pascal Mindermann

SUPPORT IN CONSTRUCTION

Daniel Colmenares, Zhitao Kong, Hannah Müller, Christoph Nething, Julian Rettig, Gabriel Rihaczek, Stephanie Rosenfeld, Meiling Sheng, Maya Smirnova, Jannik Stang, Gabriel Stephan, Konstan-tin Wulle

STATIC REPORT

Ivan Tomovic, Jonas Kappes, Marc Hymans

FUNDING

German Research Foundation (DFG)

Daria Kovaleva

Dipl.-Arch.Research Assistant