Closed-loop production of lightweight concrete components

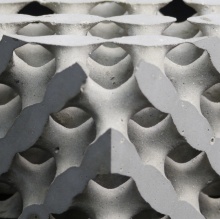

In the face of climate change and increasing resource scarcity, the construction industry is confronted with the need to drastically reduce resource consumption, emissions and waste. The application of lightweight construction principles in combination with circular production processes offers a comprehensive approach to this problem. As part of the DFG-funded Priority Program SPP 2187: "Adaptive modularized constructions made in flux", this project is concerned with the development of a zero-waste production of lightweight concrete components using fully recyclable sand formworks. The additive manufacturing of water-soluble formwork bodies made of sand and organic binder enables almost unlimited freedom in the design of weight-minimized concrete structures and full avoidance of waste due to the reusability of the formwork material.

Particle bed 3D printing of formworks

As part of the research project, a pilot 3D printing unit was designed and built with a 70 cm × 100 cm × 40 cm3 powder bed volume. The system is modular and can be extended along the X-axis to increase the printing area and add more modules to the production line. The system has been tested in the production of formworks for small and medium-sized reinforced concrete components, including topologically optimized filigree concrete beams with complex spatial structure.

PROJECT TEAM

Institute for Lightweight Structures and Conceptual Design, University of Stuttgart

Dipl.-Arch. Daria Kovaleva

Institute for Control Engineering of Machine Tools and Manufacturing Units, University of Stuttgart

Maximilian Nistler M.Sc

PROJECT FUNDING

German Research Foundation (DFG)

RELATED PUBLICATIONS

Kovaleva, D.; Nistler, M.; Verl, A.; Blandini, L.; Sobek, W.

Zero-waste Production of Lightweight Concrete Structures with Water-Soluble Sand Formwork

Proceedings of The 3rd RILEM International Conference on Digital Fabrication with Concrete (Digital Concrete 2022), Loughborough, UK, 2022, https://doi.org/10.1007/978-3-031-06116-5_1

Kovaleva, D.; Nistler, M.; Blandini, L.; Sobek, W.; Verl, A.:

Rezyklierbare Sandschalungen: Auf dem Weg zur Kreislaufproduktion leichter Betonbauteile

Beton- und Stahlbetonbau (5), 2022, https://doi.org/10.1002/best.202200009

Nistler, M.; Kovaleva, D.; Tepper, L.; Blandini, L.; Sobek, W.; Verl, A.

Camera-based Process Monitoring for Powder Bed Additive Manufacturing in Construction

Proceedings of the 55th CIRP Conference on Manufacturing Systems (CIRP CMS 2022), https://doi.org/10.1016/j.procir.2022.05.021

Daria Kovaleva

Dr.-Ing.Research Assistant